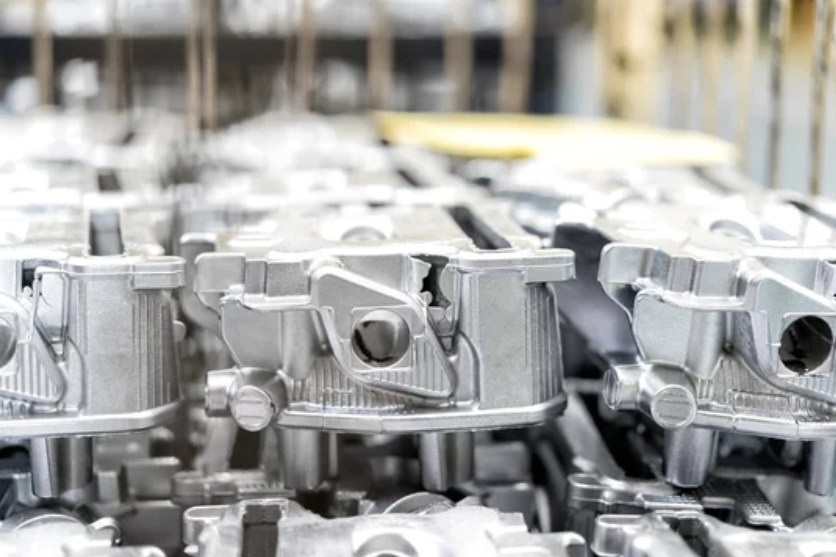

Precision aluminum casting applications across engineering sectors

Wiki Article

How Factory Solutions Enhance Manufacturing Performance and Quality in Industrial Applications

Factory solutions play a crucial role in improving production effectiveness and top quality throughout numerous commercial applications. By implementing sophisticated metal casting methods, these solutions assure components are manufactured with precision and consistency. This not only reduces preparations yet additionally decreases waste, cultivating far better cooperation in between manufacturers and foundries. The impact of premium elements on operational performance increases essential questions about the future of industrial manufacturing. What technologies exist in advance in this progressing landscape?The Function of Factory Services in Streamlining Production Processes

Furthermore, factories often offer expertise in alloy advancement, making it possible for producers to use innovative materials that improve item efficiency. The collaboration between manufacturers and foundries promotes a much better understanding of production requirements, resulting in maximized processes and enhanced product designs. By leveraging foundry services, producers can accomplish greater versatility, adapt to altering market demands, and maintain competitiveness in the industry. On the whole, the duty of shop solutions is essential in helping with a much more effective and affordable manufacturing landscape.

Advanced Technologies in Foundry Procedures

Cutting-edge modern technologies are changing shop procedures, markedly enhancing performance and accuracy. Automation plays an essential role, with robot systems simplifying recurring tasks such as molding and material handling. In addition, improvements in computer-aided style (CAD) and computer-aided manufacturing (WEB CAM) systems make it possible for factories to create intricate geometries with higher accuracy and lowered material waste.Furthermore, the integration of fabricated knowledge (AI) and artificial intelligence improves quality control by monitoring procedures in real-time and anticipating prospective issues prior to they happen. Using innovative materials, such as light-weight alloys and composites, better improves the efficiency characteristics of cast items.

3D printing modern technology is revolutionizing prototyping and tooling, enabling for quick customization and decreased lead times. Jointly, these advanced technologies not only boost manufacturing efficiency however likewise assure that the end products meet rigid top quality criteria, positioning factories at the leading edge of contemporary commercial applications.

Lowering Lead Times Through Efficient Factory Practices

Effective shop techniques play an important function in reducing lead times within manufacturing atmospheres. By applying structured manufacturing procedures and progressed organizing methods, suppliers can boost operations and maximize source appropriation. These renovations not just speed up outcome yet likewise add to general operational effectiveness.Streamlined Production Processes

Streamlining manufacturing procedures is crucial for lowering preparations in the production market. Effective factory practices, consisting of maximized process and resource management, play a crucial role in attaining this objective. By reducing waste and enhancing interaction among teams, shops can considerably enhance their operational effectiveness. The application of standard treatments also adds to constant quality and faster turn-around times, enabling suppliers to respond even more quickly to market demands. In addition, the combination of innovative innovations, such as automation and real-time monitoring systems, helps in recognizing bottlenecks and facilitating prompt interventions. On the whole, a concentrate on streamlined manufacturing processes not just accelerates preparations but likewise boosts the general competitiveness of industrial applications, making certain that products fulfill customer expectations properly.Advanced Scheduling Techniques

Efficient manufacturing processes normally lead manufacturers to check out innovative scheduling methods as a means to further minimize preparations. By employing advanced formulas and software, foundries can enhance operations, aligning production routines with need projections and resource accessibility. Methods such as Just-In-Time (JIT) organizing minimize inventory expenses while making certain timely material shipment, consequently boosting functional efficiency. Furthermore, incorporating real-time information analytics allows foundries to anticipate prospective hold-ups and change timetables proactively. This flexibility not just streamlines procedures yet additionally boosts overall productivity. Collaborative planning with customers and suppliers can foster a more synchronized supply chain, further reducing lead times. Inevitably, these innovative organizing methods equip factories to accomplish higher effectiveness and exceptional top quality in their manufacturing processes.Guaranteeing Precision and Top Quality in Steel Casting

Guaranteeing accuracy and high quality in metal spreading calls for a careful technique that encompasses every phase of the manufacturing process. This procedure starts with careful design and design of the molds, guaranteeing they can hold up against the liquified metal's temperature and stress. The choice of top notch raw products is vital, as pollutants can compromise the last product.Once the products are prepared, exact temperature control throughout melting and pouring is essential to achieve the wanted properties in the actors metal. Keeping track of solidification and air conditioning rates additional guarantees dimensional precision and surface area finish.

Quality guarantee practices, such as non-destructive screening and evaluation, are essential to determining issues early at the same time. aluminum casting. In addition, employing proficient personnel that understand the subtleties of steel spreading adds significantly to keeping high standards. Generally, these techniques collectively improve the integrity and efficiency of cast elements in numerous commercial applications

Reducing Waste and Maximizing Resource Use

Additionally, reusing scrap steel within the factory itself can significantly decrease waste, transforming byproducts right into usable resources. Lean making concepts also add to throw away reduction by improving processes and removing unnecessary steps, bring about extra reliable operations.

Routine upkeep of devices guarantees peak efficiency, avoiding failures that can result in lost materials. By concentrating on these techniques, shops not only lower expenses yet likewise add to sustainable techniques, lining up with the expanding demand for ecologically responsible manufacturing approaches in industrial applications.

The Affordable Advantage of High-Quality Parts in the Market

High-grade elements give a considerable affordable advantage in the factory market, where accuracy and resilience are extremely important. Makers that prioritize exceptional products and craftsmanship can improve item efficiency and reliability, causing raised customer contentment. This advantage is particularly obvious in sectors such as automotive and aerospace, where element failing can have tragic consequences.Furthermore, high-grade components frequently lead to reduced upkeep prices and extended product lifespans, which can be attractive selling factors for prospective customers. As market needs expand for sustainable and efficient technologies, the emphasis on quality becomes even more critical. Companies that buy high-quality foundry solutions not just enhance their production processes but additionally separate themselves from rivals that may sacrifice top quality for cost financial savings. As a result, the commitment to premium elements ultimately translates right into a more powerful market position and long-term organization success.

Frequently Asked Questions

What Sorts of Materials Do Foundry Provider Commonly Collaborate With?

Foundry solutions usually deal with steels such as aluminum, steel, brass, and iron, in addition to numerous alloys. They likewise handle products like ceramics and compounds, catering to varied industrial demands and specifications in making processes.Just How Do Foundry Provider Impact Overall Supply Chain Monitoring?

Foundry solutions considerably improve supply chain administration by streamlining product sourcing, reducing lead times, and making certain consistent top quality. Their ability to supply customized services cultivates collaboration among stakeholders, inevitably enhancing general functional effectiveness and responsiveness in manufacturing.What Industries Advantage Many From Factory Providers?

Industries such as automobile, customer, aerospace, and building and construction items greatly take advantage of factory solutions. These sectors rely on precision spreadings to fulfill stringent high quality criteria and boost their overall manufacturing processes and item efficiency.Are Shop Services Environmentally friendly and lasting?

Foundry solutions can be eco friendly and sustainable, especially when using innovative modern technologies and processes - Aluminum Foundry. Innovations such as recycling materials, reducing emissions, and optimizing power usage add to decreasing their eco-friendly influence in commercial applications

Just How Can Business Choose the Right Foundry Company?

Business can choose the appropriate shop provider by examining know-how, production capabilities, top quality accreditations, technology utilized, customer testimonials, and sustainability methods while ensuring placement with their particular project demands and long-term organization goals.Shop services play an important duty in improving manufacturing efficiency and top quality across different industrial applications. The partnership in between makers and shops promotes a far better understanding of production requirements, leading to enhanced processes and improved Aluminum Casting Company item styles. Reliable foundry methods play a vital duty in reducing lead times within manufacturing settings. By employing advanced formulas and software, factories can enhance operations, aligning production timetables with need forecasts and resource accessibility. Firms that invest in premium shop solutions not only boost their production processes however additionally differentiate themselves from competitors who may compromise top quality for price savings.

Report this wiki page